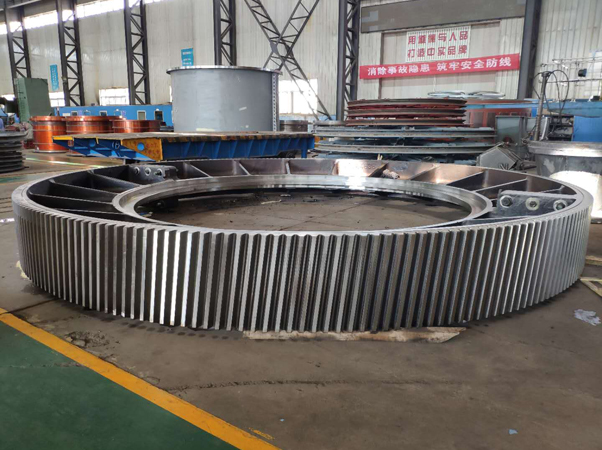

Girth Gear Manufacturer

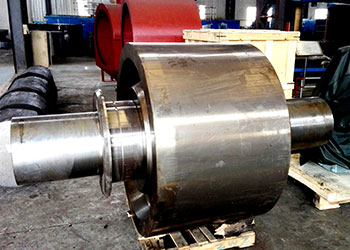

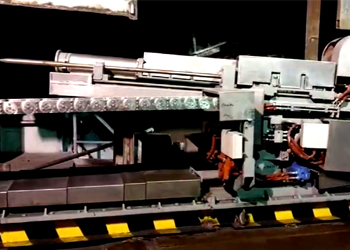

CIC girth gear manufacturer is the casting & forging center in central-south China, We mainly manufacturer, ball mill girth gear, rotary kiln girth gear and mill girth gear, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VOD refining furnace, etc. We can pour 350t liquid steel one time and yields more than 200,000t of high-quality liquid steel and can produce the high-quality steel of more than 260 steel grades such as carbon steel, structural alloy steel and the structural steel, refractory steel and stainless steel of special requirement. The maximum weight of casting, gray casting, graphite cast iron and non-ferrous casting is 200t, 30t, 20t and 205t separately.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語