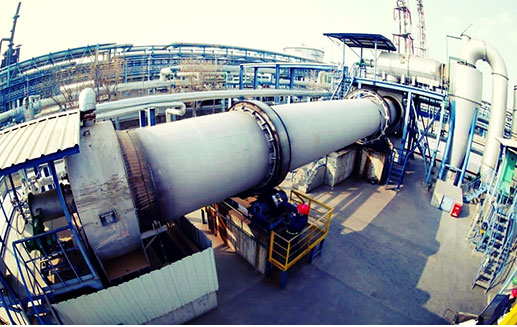

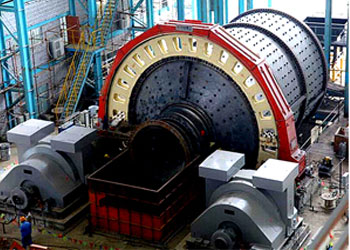

Cement Rotary Kiln

Since 1950s, CIC rotary kiln manufacturer had started manufacturing of pyro processing equipment. These series of pyro processing rotating kiln equipment were used in various fields, that enforce us to overcome many difficulties. Nowadays, our rotary kiln in cement industry meets the incineration requirements of this equipment for various materials. The complete sets of the pyro processing heavy equipment and machinery CIC rotary kiln manufacturer can provide includes the dry, semi-dry and wet-processed cement rotary lime kiln, self-return soda steam calciner, metallurgy rotary kiln, environmental dryer and cooler, etc which are widely used in the industries of cement producing, metallurgy, chemical, environment protecting and ,etc.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語