CIC heavy industry's products cover more than 10 fields, such as mining, metallurgy, building materials, marine, petrochemical industry, new energy and related supporting automation control, engineering plastics, high-power reducer, and large castings and forgings. It is a heavy machinery manufacturing base in Central China.

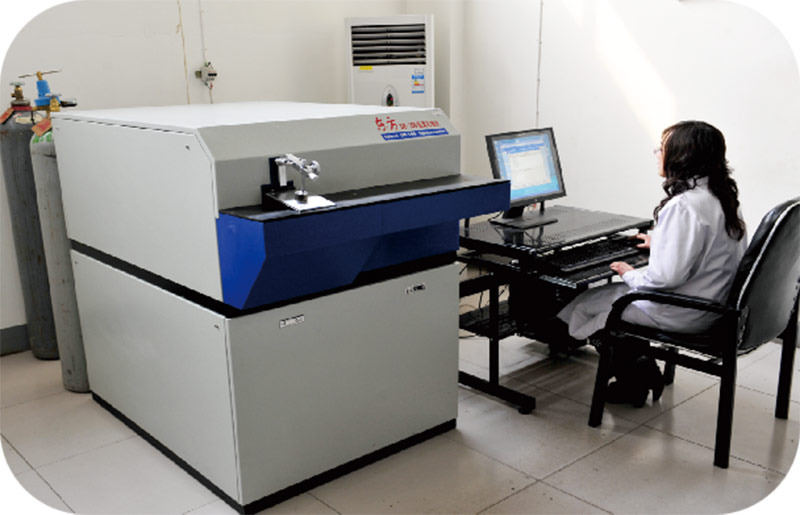

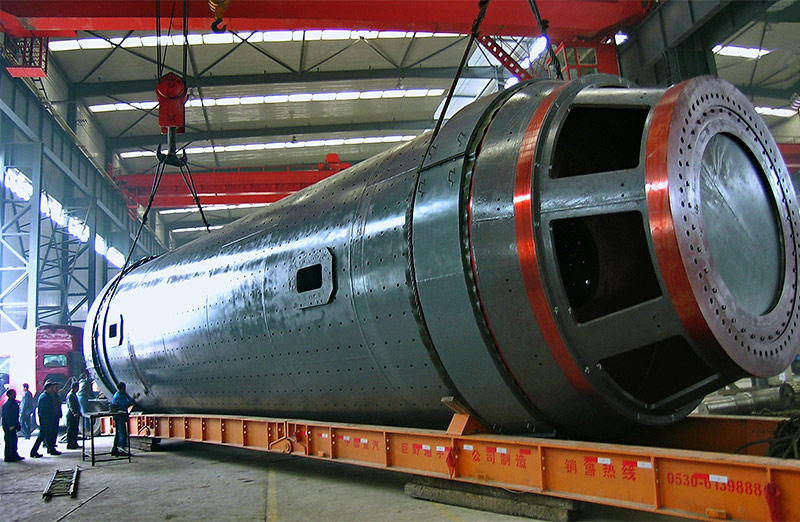

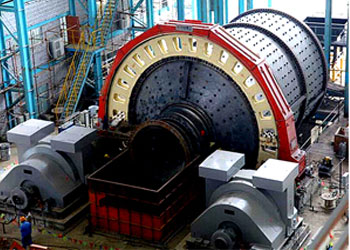

Our rich experience in equipment manufacturing enables us to complete customized equipment manufacturing according to the various needs of customers. Each individual equipment, such as mining ball mill, rotary kiln machine, and so on, their grinding function and incineration function play a key role in many industries. Due to the difference in material handling, output, and application site, strict experimental research, and data support are required for each piece of equipment in the design and manufacturing process. Our laboratory can carry out a large number of experiments and calculations, aim to realize customized equipment manufacturing for customers. Our customized equipment meets the needs of customers and reaches the production capacity and standard, finally transform into the interests of customers.

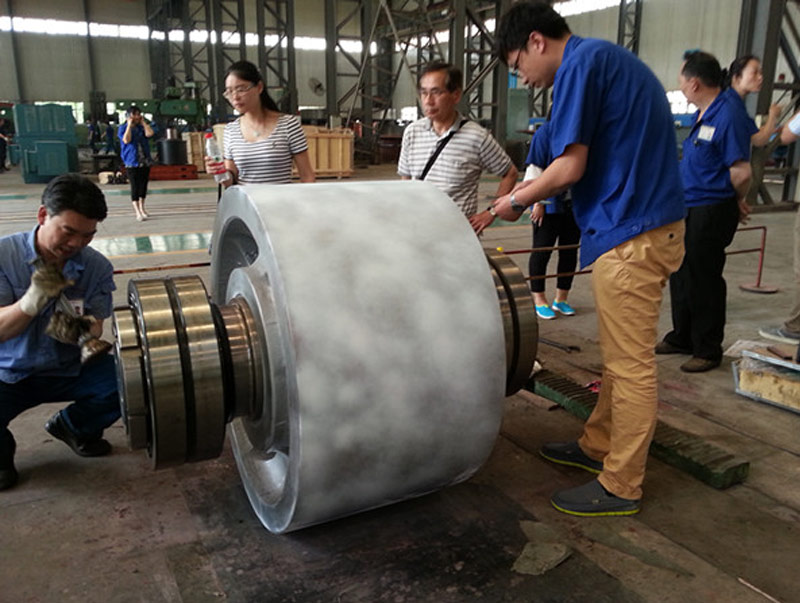

Customized equipment manufacturing can be divided into special material equipment manufacturing, special process equipment manufacturing, special size equipment manufacturing, and other non-standard products. In the customized equipment we have done in the past, we not only get the satisfaction of customers, but also the praise of our manufacturing ability.

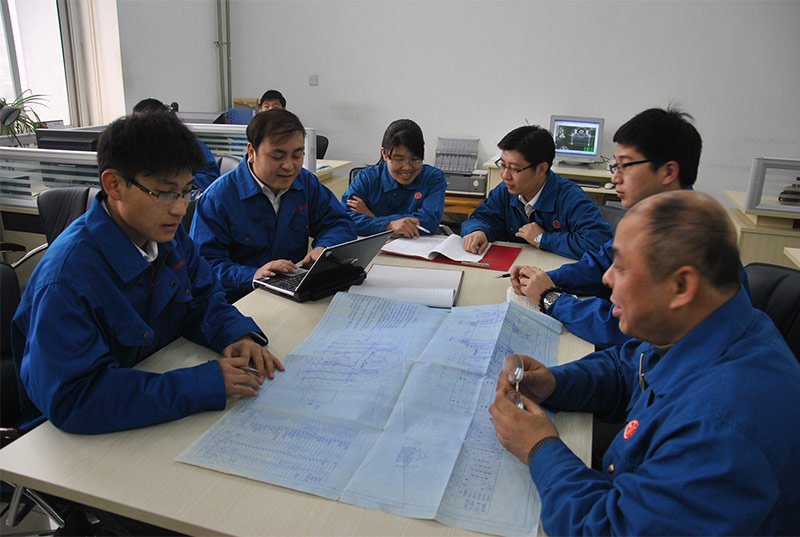

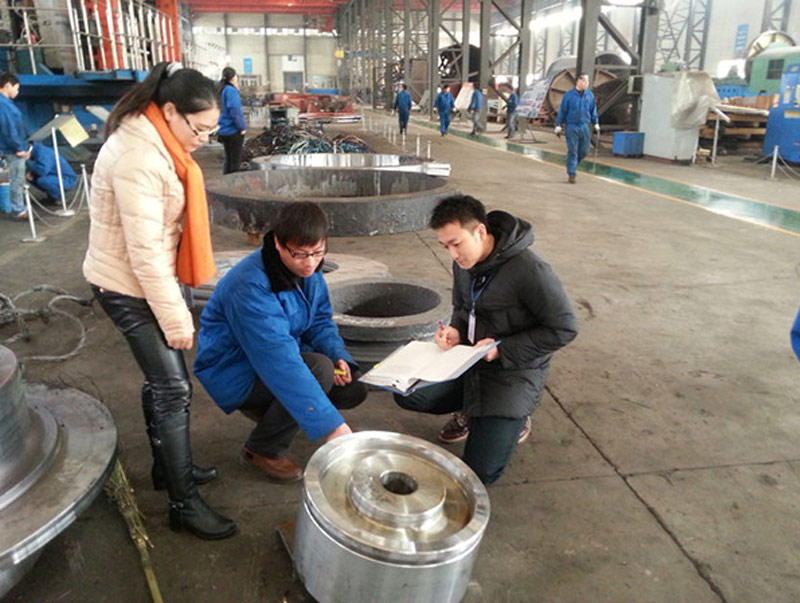

To achieve equipment customization services, mainly rely on our strong technical team. By 2020, our company has 8 senior engineers, 70 engineers, and 92 assistant engineers. Through long-term cooperation with customers from all over the world, we are familiar with the technical and quality standards of various countries, and manning quality inspectors who are specially responsible for the follow-up of the production process. Our customized equipment manufacturing aims at "serving customers' needs and making them satisfied" to enhance the recognition and popularity of the CIC brand in the international market.

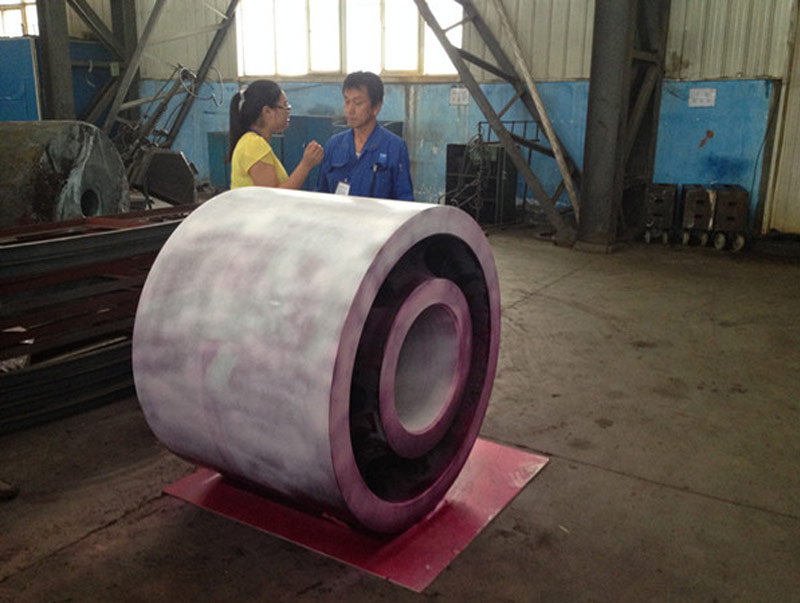

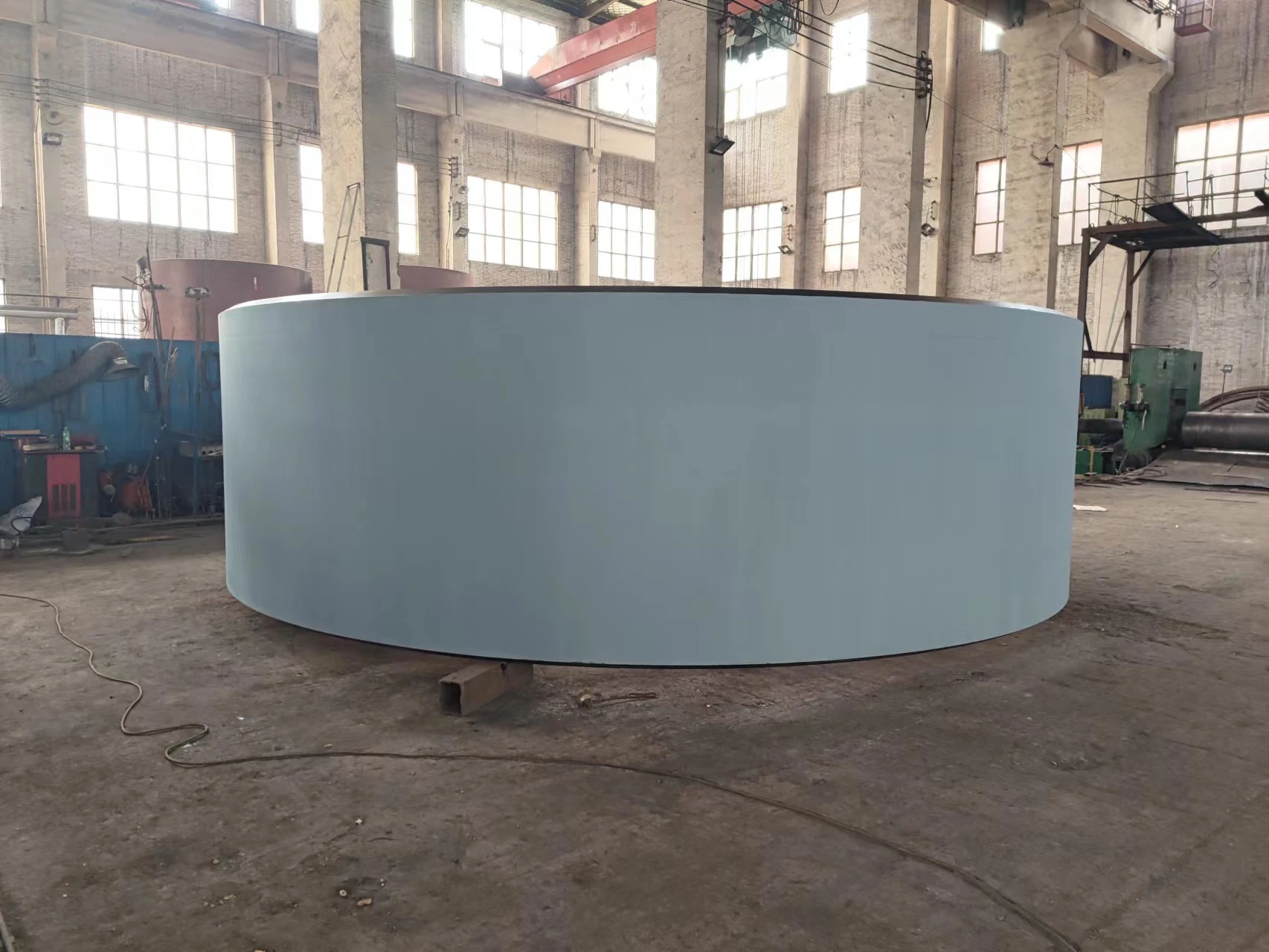

Case 4 Special Super-thick Shell Project

This project is exported overseas, as an important part of the cement rotary kiln connecting multiple coolers. There are 3 shell sections in total, with an inner diameter of 5800mm and a maximum plate thickness of 120mm. The material is Q245R normalized plate. After 4 months of production, the three-party final inspection passed.

Highlight 1: The thickest plate is 120mm, which is far greater than that of ordinary rotary equipment. Our riveting and welding factory has overcome various difficulties, made breakthroughs and innovations, and successfully completed the rolling process.

Highlight 2: There are 10 evenly divided elliptical flange holes on the cylinder wall with a plate thickness of 120mm. Cutting and welding of flange holes have high requirements for accuracy, finally, it meeting the requirements of dimensional testing and template testing.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語