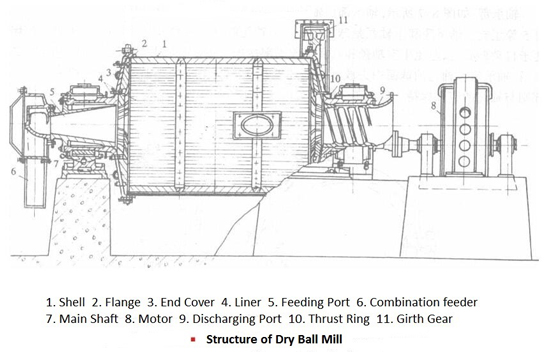

Dry Ball Mill

Dry ball mill is suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and other building stones, or products that require storage and sales in the form of powder. In addition,among all ball grinding machine, if the concentrator is located in an arid area and water resources are scarce, dry grinding ball mill can be used for water saving.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語