Features of Overflow Mill

Overflow mill is easy to start, stable operation

Simple structure, convenient maintenance

Various working modes and optional granularity

The grinding time is short and the service life is long

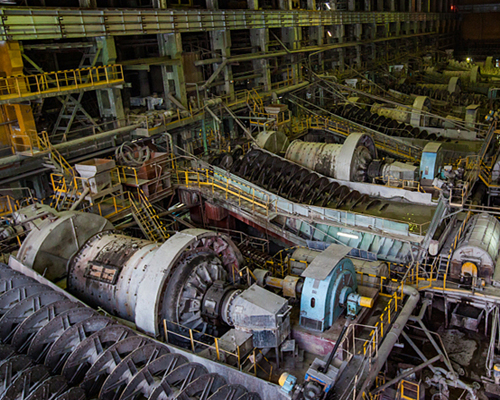

Application of Overflow Ball Mill

Overflow ball mill is often used for grinding fine ore or regrinding concentrate in mineral processing industry, such as cement ball mill. In addition, it can also be used in silicate products, building materials, chemical fertilizers, non-ferrous metals, glass ceramics and other production industries.

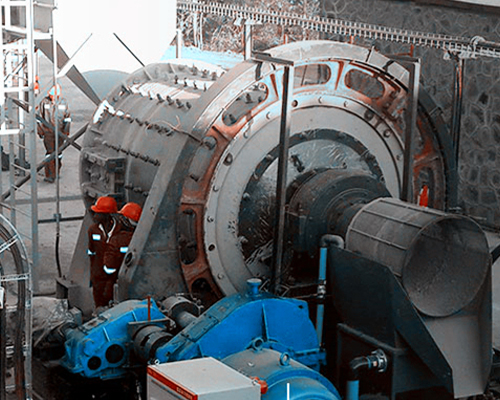

Working Principle of Overflow Ball Mill

When overflow mill is working, raw materials and water are continuously added from one port, and the slurry is formed after being ground by steel ball inside the cylinder. After the slurry is ground to the target size and accumulated to a certain height, it will overflow from the other end.

Advantages of Overflow Ball Mill

Rich Experience: We have produced hundreds of overflow ball mills every year. We ensure the quality and provide after-sales service. The ball mill grinding machine has a long service life.

Strong Production Capacity: We can make quick delivery with our 6 factories and 800+ workers.

Reasonable price: We have long-term cooperation with hundreds of suppliers, and will lower the cost of raw materials and processing.

Intelligent Grinding Expert System-Ball Mill

To realize the intelligent control for ball mill operation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient. Learn More...

Technical Properties List of Overflow Ball Mill

| Specification | Shell Diameter | Shell Length | Volume | Rotary Speed | Grinding Medium Load | Transmission Type | Motor | Profile Dimensions | Total Weight | Remarks |

| mm | mm | M3 | r/min | t |

| Power(kw) | Rotary Speed(r/min) | (L×W×H)m | t |

|

| MQY15×30 | 1500 | 3000 | 5 | 26.6 | 9 | Side-edge Transmission | 95 | 742 | 7.4×3.4×2.8 | 18.5 | Drum Feeder |

| MQY15×36 | 1500 | 3600 | 5.7 | 26.6 | 10.6 | 95 | 742 | 8.0×3.4×2.8 | 17.22 | Rubber Liners |

| MQY18×61 | 1830 | 6100 | 13.4 | 24.5 | 24.6 | 220 | 736 | 10.2×5.1×4.0 | 37.32 |

|

| MQY21×30 | 2100 | 3000 | 9.4 | 22.1 | 15 | 200 | 740 | 8.5×4.65×3.0 | 45 |

|

| MQY24×30 | 2400 | 3000 | 12.2 | 21 | 22.5 | 250 | 980 | 8.8×4.7×4.4 | 55 |

|

| MQY24×70 | 2400 | 7000 | 26.66 | 21 | 48 | 475 | 740 | 14.3×5.8×4.4 | 67 | Rubber Liners |

| MQY27×36 | 2700 | 3600 | 18.5 | 20.5 | 39 | 400 | 187.5 | 10.4×5.8×4.7 | 61.34 |

|

| MQY27×40 | 2700 | 4000 | 20.5 | 20.24 | 38 | 400 | 187.5 | 9.8×5.8×4.7 | 70 |

|

| MQY27×45 | 2700 | 4500 | 23.5 | 20.5 | 43.5 | 500 | 187.5 | 12.5×5.8×4.7 | 76 |

|

| MQY27×40 | 2700 | 4000 | 34.34 | 19.5 | 53 | 630 | 589 | 13.5×5.9×4.7 | 71.2 | Rubber Liners |

| MQY28×54 | 2800 | 5400 | 30 | 19.5 | 55.2 | 630 | 167 | 13×5.83×4.7 | 97.8 |

|

| MQY28×80 | 2800 | 8000 | 43 | 20 | 78.6 | 800 | 137 | 16.5×7.3×5 | 115 | For coal water slurry |

| MQY30×110 | 3000 | 11000 | 69.2 | 17.3 | 100 | Central Transmission | 1250 | 429 | 28.9×3.8×5.0 | 227.8 |

|

| MQY32×36 | 3200 | 3600 | 26.3 | 18.3 | 48.4 | Side-edge Transmission | 500 | 167 | 14.3×7.3×6.0 | 116.94 |

|

| MQY32×40 | 3200 | 4000 | 29.2 | 18.2 | 60 | 560 | 980 | 16.7×7.3×6.0 | 121.4 |

|

| MQY32×45 | 3200 | 4500 | 32.9 | 18.3 | 60.5 | 630 | 167 | 13×7.0×5.82 | 124.23 |

|

| MQY32×54 | 3200 | 5400 | 39.4 | 18.3 | 73 | 800 | 167 | 14.2×7.0×5.82 | 129 |

|

| MQY32×64 | 3200 | 6400 | 46.75 | 18.3 | 86 | 1000 | 167 | 15.2×7.0×5.8 | 140 |

|

| MQY32×75 | 3200 | 7500 | 55.5 | 18.3 | 102 | 1250 | 734 | 17.7×8.4×6.3 | 154 |

|

| MQY32×90 | 3200 | 9000 | 64.2 | 18.3 | 106.6 | 1250 | 150 | 18.5×7.3×6.0 | 173 |

|

| MQY34×45 | 3400 | 4500 | 37 | 18.4 | 74.6 | 800 | 167 | 11.5×7.0×6.1 | 129.8 |

|

| MQY34×56 | 3400 | 5600 | 45.8 | 17.9 | 84.3 | 1120 | 985 | 16.7×7.6×6.13 |

|

|

| MQY36×45 | 3600 | 4500 | 41.4 | 17.25 | 76 | 1000 | 167 | 13×7.3×6.3 | 144.1 |

|

| MQY36×50 | 3600 | 5000 | 46.7 | 17.5 | 85.96 | 1250 | 167 | 15×7.6×6.2 | 150 |

|

| MQY36×50 | 3600 | 5000 | 46.7 | 17.3 | 85.86 | Central Transmission | 1250 | 429 | 23×4.6×6.3 | 176 |

|

| MQY36×56 | 3600 | 5600 | 55.4 | 17.76 | 106.3 | Side-edge Transmission | 1250 | 750 | 14.4×8.0×6.3 | 159.7 |

|

| MQY36×60 | 3600 | 6000 | 55.7 | 17.3 | 1002.5 | Central Transmission | 1250 | 429 | 24×4.6×6.3 | 138.73 |

|

| MQY36×60 | 3600 | 6000 | 54 | 17.3 | 102 | Side-edge Transmission | 1250 | 167 | 15.6×8.3×6.3 | 162.7 |

|

| MQY36×61 | 3600 | 6100 | 55.36 | 17.76 | 106.3 | 1200 | 980 | 15.8×8.5×6.2 | 164.1 |

|

| MQY36×85 | 3600 | 8500 | 79 | 17.4 | 131 | 1800 | 743 | 20×8.2×7.1 | 251.89 |

|

| MQY36×90 | 3600 | 9000 | 83.5 | 17.4 | 138 | Central Transmission | 1800 | 743 | 28×4.6×5.6 | 286 |

|

| MQY38×67 | 3800 | 6700 | 70 | 16.5 | 130 | Side-edge Transmission | 1400 | 743 | 19×8.2×7.1 | 185.3 |

|

| MQY40×60 | 4000 | 6000 | 69.8 | 16 | 126 | 1500 | 200 | 17.4×9.5×7.6 | 203.5 |

|

| MQY40×67 | 4000 | 6700 | 69.8 | 16 | 136.3 | 1600 | 200 | 15.6×9.6×7.3 | 206.2 |

|

| MQY40×135 | 4000 | 13500 | 155 | 16 | 233 | 3300 | 200 | 23×10×4.9 | 343 | For coal water slurry |

| MQY43×61 | 4300 | 6100 | 80 | 15.67 | 144 | 1750 | 200 | 14×10×7.7 | 215.3 |

|

| MQY50×64 | 5030 | 6408 | 120 | 14.4 | 251 | 2600 | 200 | 14.6×11×9.1 | 318.5 |

|

| MQY50×83 | 5030 | 8300 | 152.3 | 14.4 | 266 | 3300 | 200 | 22×10.5×9 | 402.6 |

|

| MQY55×65 | 5500 | 6500 | 143.3 | 13.8 | 264 | 3400 | 200 | 18.5×9.8×8.9 | 451.5 |

|

| MQY55×85 | 5500 | 8500 | 187.4 | 13.8 | 335 | 4500 | 200 | 20.5×12×9.8 |

|

|

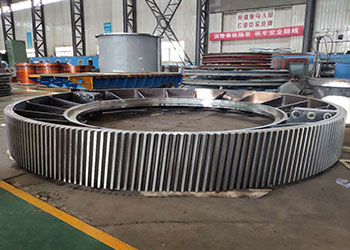

Spare Parts & Services of Overflow Ball Mill

Grinding Mill Parts

Customized and matched mill parts and components (including end cover, shell, hollow shaft, liner, main bearing, girth gear, pinion, and gear) designed to improve heavy equipment machinery reliability. From component suppliers to full-service partners, CIC can support you no matter what brand of mill you are making.

Mill Liners

We have the most complete range of mill liner products in the market and we can provide you with the best solution to meet the specific needs of the mill, which make your mill out of the ordinary.

Grinding Service

Whether you want to minimize maintenance downtime, increase production and reduce tonnage costs, or improve efficiency, we are here to support you.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland  日本語

日本語