0086-379-64087240

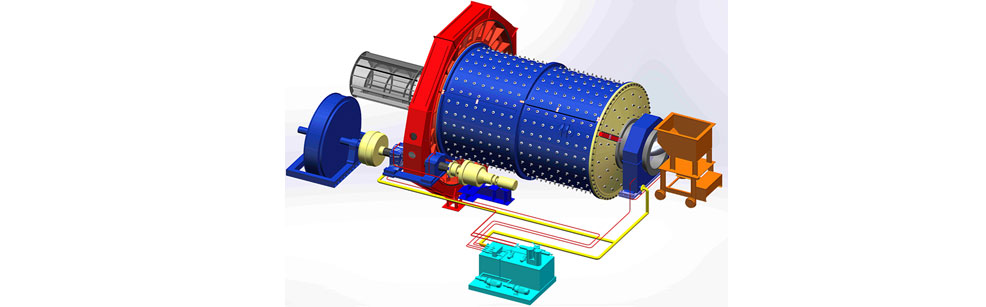

Independent design and manufacture can be achieved according to customer demand and different working conditions. CIC grinding machine suppliers use professional and advanced software, such as ANSYS, STRAND, JMATPRO, DEFROM, MAGMA, SOLID WORK and so on to analyze the simulation assembly and operation of the key parts and the whole grinding mill. Through the early process selection, research and development design, as well as after-sales installation and maintenance, we could provide you with one-stop mining heavy machinery service at any time and with the solutions to help optimize your operation. Inquiry grinding mill price directly from heavy machinery manufacturers.

As a grinding mill manufacturers, CIC can produce a variety of large industrial grinding mill machine including Overflow Ball Mill, Wet Grid Ball Mill, Dryer Ball Mill, Rod Mill, SAG Mill. We have more than 60 years of big grinding mill machine production experience and have always been an heavy equipment machinery pioneer in innovative technology.

With more than 60 years of experience in ball mill technology, CIC ball mills are designed for consistent and dependable performance, as well as long life and minimum maintenance. Ores and various kin...

The rod mill is very similar to the ball mill, but the rod mill uses a steel rod as the grinding medium. The feeding of the rod mill is about 50 mm.

The role of the SAG mill can be used for two or three-stage crushing and screening grinding operations. SAG mills are often used in grinding operations in modern concentrators.

Process Selection

According to the china ball mill ore sample provided by the customer, the parameters of ore crushing and grinding are measured. Through the simulation of JKSimMet computer software, the best SAG mill and Ball mill specifications and parameters are settled.

Strength

Finite element analysis is commonly used to calculate the strength of the industrial grinding mill machine barrel, end cover, and hollow shaft to determine the optimal structural parameters.

Transmission

According to the industrial grinding mill machine power and working conditions, you can choose:

1. Single motor gear drive;

2. Dual-motor gear drive;

Perform torsional vibration analysis of the transmission system to avoid resonance.

Main bearing

According to the industrial grinding mill specifications and load conditions, three types of dynamic and static pressure, static pressure and sliding shoe bearings can be selected, and the corresponding special lubrication station can be configured.

Auxiliary machine

1. Optimization of the structure of the feeding and discharging device (feeding trolley, discharge drum screen).

2. Use liner simulation software to study the geometry of the liner.

3. High-strength bolt strength calculation by software improved industrial grinding mill machine reliability and service life.

Control

Through PLC control, touch screen display and operation, as well as the measurement and monitoring of temperature, vibration, oil pressure, oil flow, oil film thickness and other parameters, and the use of DCS system, the reliability of industrial grinding mill machine operation is improved.

Sub-supplier

The preferred domestic and foreign well-known supporting suppliers provide the best configuration for the industrial grinding mill machine.

CIC has an intelligent grinding expert system, which can monitor the real-time operation of the ball mill, collect and analyze the grinding status and material parameters. It can ensure the efficient and safe operation of the mill.

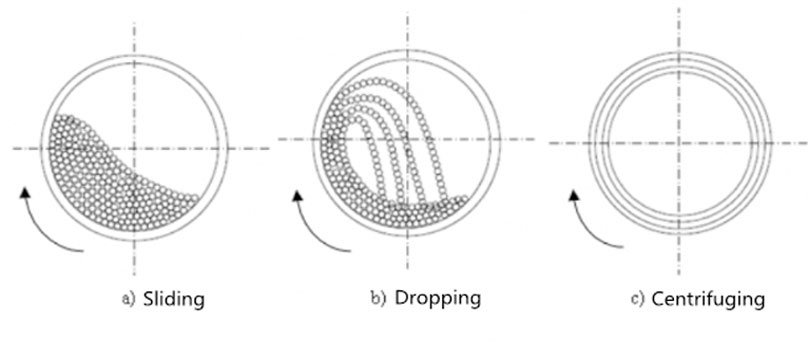

From low speed to high speed of ball mill cylinder revolution, the medium movement state can be divided into three types:

lThe falling state (Fig. a) the industrial grinding mill machine has a falling motion state when it is running at low speed. The materials are mainly crushed by the crushing and grinding action when the media slide each other.

lDrop state (Fig. b) when the industrial grinding mill machine is running at a high speed, the drop state occurs. At this time, the crushing process is dominated by impact, followed by grinding. Ball mill generally works in this case.

lCentrifugal state (Figure C) when the cylinder speed rises to a certain limit value, that is, when it reaches or exceeds the critical speed, all the media will not fall with the rotation of the cylinder, which is the centrifugal state of the media. Under the condition of centrifugal motion, there is no grinding effect.

Dry ball mill is used for grinding materials that can't add water, such as cement, building materials, etc. In order to avoid environmental pollution caused by dust, it is necessary to add auxiliary equipment such as air guiding device, dust pipe and dust collector. Cement grinding mill and mineral grinding mills have better finished products, low failure rate, low loss of steel ball and liner.

Wet ball mill is used for grinding materials that can add water, such as ore, chemical industry, etc. Although no other auxiliary equipment is needed, water should be added continuously during operation, which increases the cost. Wet industrial grinding mill machine has high grinding efficiency, wide range of application, can keep continuous production, and no environmental pollution caused by dust.

Export Country:Senegal

Company Name:SORED MINES S.A

Type:Φ3.03×3.03m Ball Mill

Test Run in the Factory

Export Country:Laos

Company Name:Democratic Republic of Congo

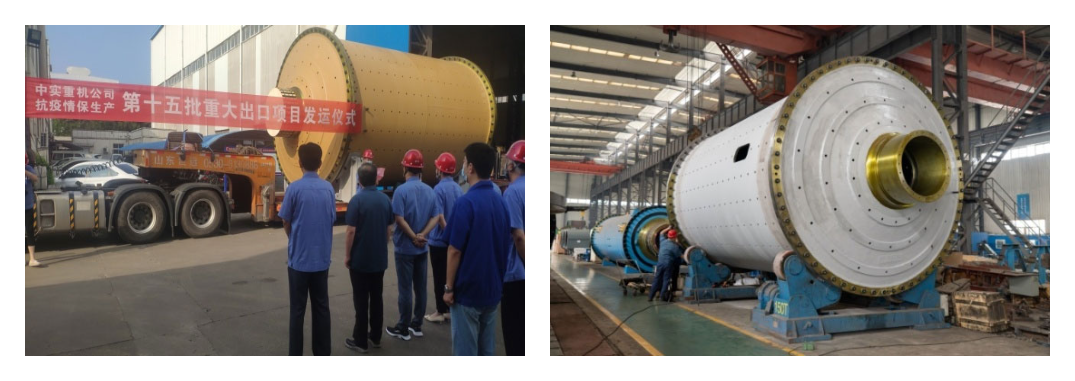

Type:Φ4.5×7.03m Overflow Ball Mill (Two sets)

Delivery from Factory

Installation Site on Site

Export Country:Russia

Company Name:PRIISK SOLOVIEVSKIY

Type:Φ5.5×3.6m SAG Mill (2 Sets),Φ4.6×6.0 Ball Mill(2 Sets)

Test Run in the Factory

Installation Site in Russia

Export Country:Peru

Company Name:SCINTIAN CORPORATION LLC

Type:Φ1.83×3m Overflow Ball Mmill

To be Delivery Installation Site in Peru

Export Country:Australia

Company Name:Rio Tinto

Type:Φ3.8×6.1m Grinding Mill Modification Service

Assembly in the Factory Delivery Ceremony

Export Country:Eritrea

Company Name:ZARA

Type:Φ3.6×5.4m Ball Mill

Site Installation

Export Country:Laos

Type:Φ3.2×5.4m Ball Mill (Two sets)

Test Run on Site