0086-379-64087240

Our company has designed a set of Intelligent Automation Expert System to comprehensively monitor the real-time operation of the mill, grinding status and material parameters. The control interface is simple, clear and beautiful, which can reflect the overall mill operation and material process flow. The interlocking and alarm settings are reasonable, and the control interface can be transmitted to the engineer's office through the wireless communication module. At the same time, the real-time running interface of the system can be viewed remotely.

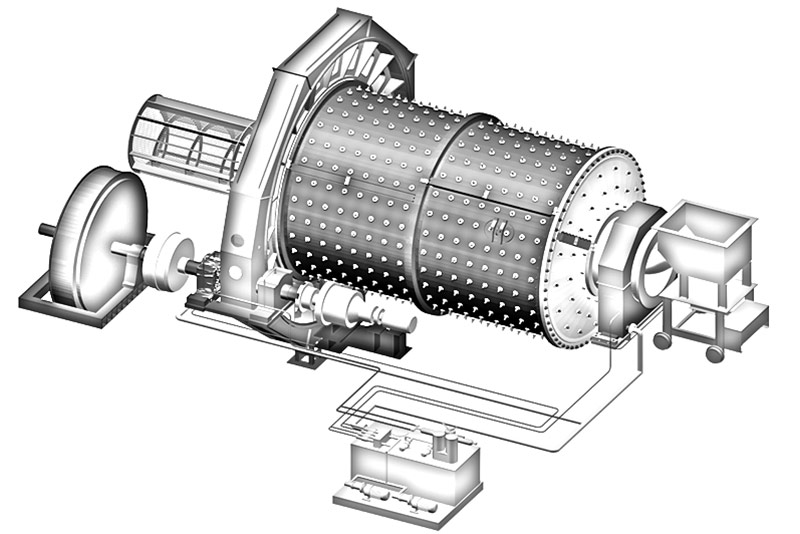

Our intelligent grinding expert system can be used in the state detection of overflow ball mill, lattice ball mill, semi autogenous grinding mill and self mill in the mining grinding mill, cement grinding mill and coal mining process industries.

It has strong generality and flexible system configuration

Perfect control function and convenient data processing

The display operation is centralized and the man-machine interface is friendly

The installation is simple and standard, and the debugging is convenient

Reliable operation

The whole system is controlled by the computer control system. According to the monitoring points and sub-functions, the monitoring control, information exchange, data processing and other functions of the whole mill operation condition and material information are completed through the central system.

The system adopts the method of spectrum analysis, which can greatly improve the sensitivity and signal-to-noise ratio of the product. At the same time, the stability, accuracy and anti-interference ability of the instrument operation is also significantly improved.

The system uses a non-contact online detection method to monitor the ore in real-time. Through data analysis, the particle size distribution characteristics of the ore are given, and the process control parameters are provided. According to the current particle size distribution and a large number of historical data, the system obtains the particle size index data, which can not only reflect the position of the current particle size distribution in a large number of historical data, but also reflect the current particle size deviation from the historical median.

For a long time, the maintenance of rotating equipment is based on the regular maintenance system of fault maintenance or preventive planned maintenance. The maintenance items, schedule and maintenance cycle are formulated by the management department according to the experience. But with the development of science and technology, the current maintenance system obviously exposes many defects. On the one hand, unnecessary maintenance is often carried out for the units with good equipment condition, which not only increases the maintenance period and cost, reduces the availability of the units, but also may cause damage to the parts and worsen the performance of the equipment due to poor maintenance quality; On the other hand, for the units with poor reliability, due to insufficient maintenance, the number of temporary inspection is increased or major equipment failure is caused, which reduces the availability of units, which will inevitably cause economic losses.

Our intelligent expert system is designed to understand the current operation status of key equipment and key equipment, judge the status change trend of the monitored machine, diagnose the fault location and severity of the monitored machine, and check and accept the effect of overhaul or temporary maintenance, so as to realize the early detection, early prediction and early diagnosis of equipment fault, and eliminate the fault in the bud. Its purpose is to improve the equipment running intact rate, reduce equipment downtime and reduce maintenance costs. At the same time, it can reduce the operation and maintenance costs and labor intensity, and achieve the purpose of reducing manpower and increasing efficiency.

The successful experience of related industries and advanced monitoring system tools can be used to implement condition monitoring technology on rotating equipment, and the accumulation and arrangement of experience should be paid attention to. Therefore, it is necessary and feasible to establish a set of condition monitoring technology and system suitable for the processing line. Using advanced monitoring equipment to monitor the main parameters of the main equipment, using software to analyze and evaluate the status of the equipment, and arranging the maintenance of the equipment. According to the analysis and evaluation results can ensure the normal operation of the equipment, can reduce or even avoid sudden equipment damage accidents, achieve the real "required repair", ensure the safe operation of the unit, and ensure that there is no excessive maintenance. It can not only save maintenance costs, but also reduce the outage time of the unit, and improve the availability of the unit.