Search

0086-379-64087240

NDT test is an important inspection method in industry manufacture field. In recent years, not only overseas customer asking for this inspection method during the products purchasing, also it is used widely in domestic products.

Non-destructive testing is a test method to check the surface and internal quality of the inspected part without damaging the working condition of the workpiece or raw material.

Commonly used inspection methods are: X-ray inspection, ultrasonic inspection, magnetic particle inspection, eddy current inspection, gamma ray inspection, penetration inspection (fluorescent inspection, color inspection) and other physical inspection methods.

Normal for the parts of building material field and mining equipment field, without any special requirement from client, we use UT, MT and PT more common.

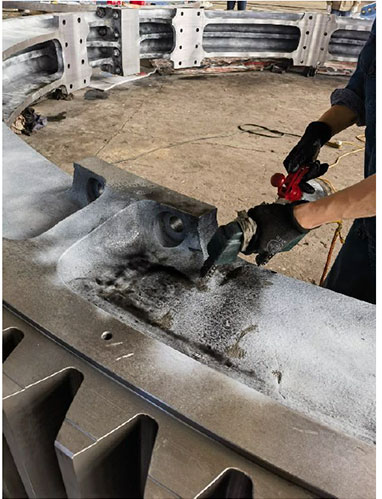

Magnetic particle testing is a testing method used to detect surface and near surface defects in ferromagnetic materials. When the workpiece is magnetized, if there are defects on the surface or near the surface of the workpiece, magnetic leakage occurs due to the increase in magnetic resistance at the defect location, forming a local magnetic field. The magnetic powder displays the shape and position of the defects here, thus determining the existence of the defects.

Contact Us

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  română

română  Nederland

Nederland